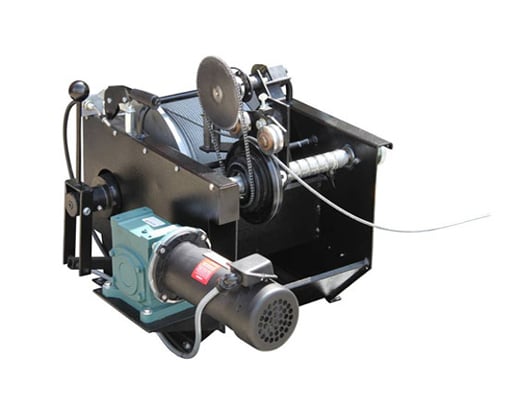

Model 25 Cam Power Winch

Driven by variable speed, high torque hydraulic (or optional electric) motor with 2,500 feet (762 m) of cable length. Features hand operated brake with eight square inches braking surface, and a dog clutch, which allows winch drum to free spin.

Overview

The winch features:

- Adjustable cable level wind

- Mechanical counter

- Mechanical footage read-out at winch

- Video depth encoder, displaying camera position at all times on TV monitor

- Variable speed control

- Choice of hydraulic or electric power sources

- Clutch Mechanism

- Emergency Disc Brake

Model 25 Winch Specifications

Application: Designed for ¼-inch steel-armored, single conductor coaxial video cable

Cable Capacity: 1,500 to 2,500 feet (457.2 to 762 m)

Drive Motor (Hydraulic Models): Variable, reversible drum speed (0-20 rpm) with nearly constant torque. (Note: Hydraulic powered winches require the installation of a hydraulic fluid source and directional control, sold separately.)

Drive Motor (Electric Models): 90 or 180 volt, variable speed DC motor reversible controller, operation from 115 VAC; right angle 30: 1 gear box designed for a maximum thrust torque of 880 load pounds

Power Source (Electric): 120/240 VAC, 50/60 Hz or AC generator

Clutch: Manual level type (dog clutch) to allow drive mechanism to be disengaged, providing free spooling of cable

Brake: Mechanical caliper disc; 8 sq. in of total braking surface; high grade friction material

Footage Counter Mechanism: Includes electronic encoder and mechanical counter on winch

Level Wind: Automatic diamond screw mechanism with adjustable calibration

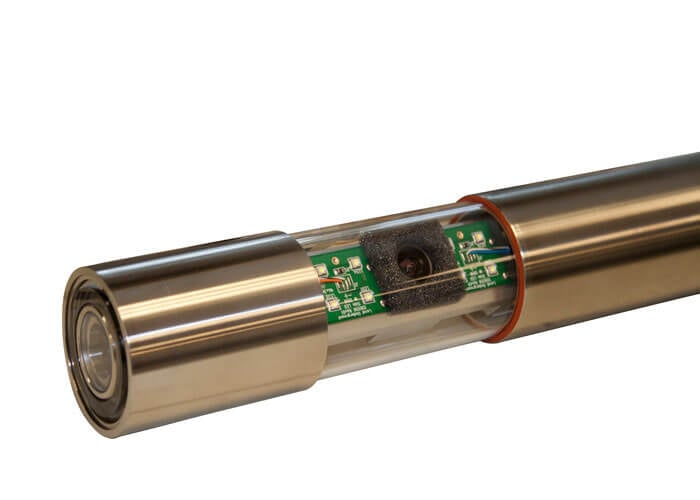

Slip Ring Assembly: Low noise slip rings permitting signal and DC power transmission over single-conductor coaxial cable

Winch Speed & Direction Control: 3-way directional valve (hydraulic motor) or variable speed controller (electric motor)

Dimensions: height 26 inches (66 cm), width 30 inches (76.2 cm), length 28 inches (71.1 cm)

Weight (without cable): 330 lbs (149.7 kg)

What Customers Say

The camera is excellent and it makes a night and day difference in our business.

Gary Shawver

Shawver Well Company

I used to borrow a friendly competitor’s camera. He had a small one with a hand reel and a tripod made of PVC. It worked for me at times, but the R-cam 1000 is heads and shoulders above that.

Scott Miller

Northern Virginia Drilling

I hoped we would use our new R-CAM 1000 at least 1 time per month... but we're averaging closer to 10. Plus, I don't have to subcontract the work out to my competition anymore, and I'm picking up a bunch of additional well rehab work.

Al Boone

Boone Water Systems, Inc

Frequently Asked Questions

The downhole facing SC-166 is suitable for boreholes up to 10 inches in diameter. The R-CAM dual view camera can view boreholes up to 16 inches in diameter. The DC5150 is suitable for borehole diameters up to 30 inches in diameter. Please note, visibility downhole will be impacted by the clarity of the fluid and the available light.

Every camera system will eventually require a repair to the cable head, the point at which the cable and camera physically connect. Over time, the internal connections within the cable head can be strained to the point where they disconnect and cause interference or a complete loss of the video signal. To expedite the repair process, we have cable head repair kits available for both portable systems and large vehicle-based systems.

Conducting surveys with the included centralizers and available lens shield accessory is the best way to ensure that the camera head remains protected downhole. When not in use, store the camera head in an area where it will be safe from unintentional drops or damage. If your camera system is damaged, we offer full repair services at our headquarters in Fresno, California.